Ball mill pinion | prmdrive

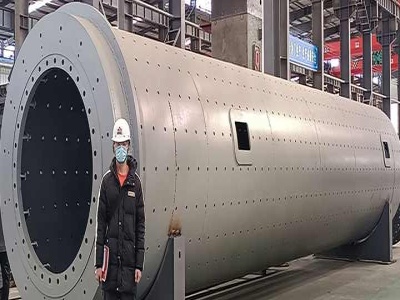

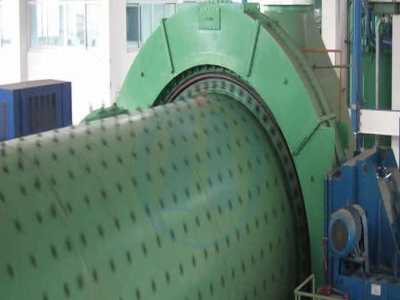

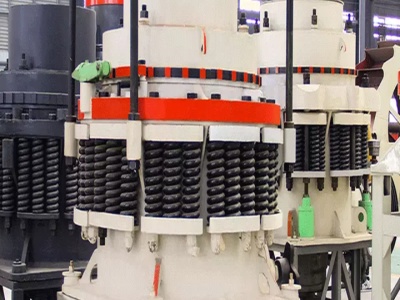

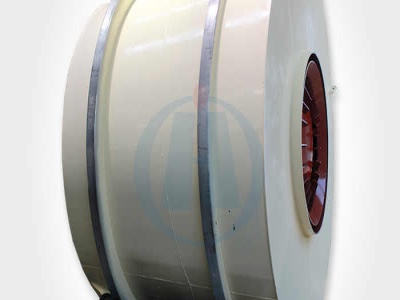

· National standard ball mill pinion module is not less than 14, commonly used gear module is 18 module, 20 module, 22 module, 24 module, 25 module, 26 module, 28 module, 30 module. The number of teeth and modulus of gears are set according to the requirements of mechanical and mechanical principles. Design of pinion for ball mill: