Copper extraction

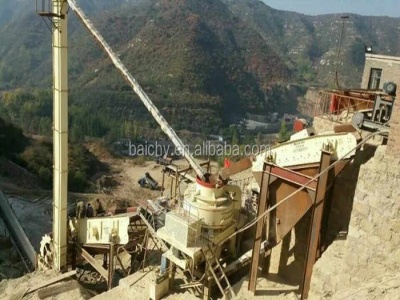

The average grade of copper ores in the 21st century is below % copper, with a proportion of economic ore minerals (including copper) being less than 2% of the total volume of the ore rock. A key objective in the metallurgical treatment of any ore is the separation of ore minerals from gangue minerals within the rock.